Pharmaceutical manufacturers must validate and reproduce certain events with 100% accuracy, as no exception is tolerated in this key health industry. Pharma firms implement several types of quality checks whether it is X-ray, visual detection systems, or check-weighing to ensure that every stage of their production line produces 100% guaranteed medicines, with zero manufacturing defects. Mettler-Toledo with its wide range of inspection systems and its presence in India provides the pharma manufacturing and packaging industries with reliable solutions.

Packaging South Asia editor Naresh Khanna and correspondent Priyanka Tanwar recently had an online interaction with Miriam Krechlok, Pharma marketing manager, and Wolf Pries, sales manager, Mettler-Toledo about the company’s inspection solutions for pharmaceutical products, and their potential appeal for Indian pharma manufacturers and co-packing facility owners. Trends of liquid drug packaging and inspection and compatibility with inkjet marking engines were also discussed.

The Mettler-Toledo product inspection devices can be used inline in highly automated packaging lines as well as offline where the manual packaging process is used. Pries mentions, “When we talk about vaccine production, for instance, these lines are processing 600 vials per minute and this is, of course, impossible to inspect offline with a manual process. In 90% or 95% of the cases, the inspection machines are inline and do their job on their own.”

According to Pries, offline inspection is mostly used when there may be a product recall, and the inspection staff is manually reinspecting the product that was recalled and identifying the batch that caused the recall. This does not have much application in the pharmaceutical industry, according to him.

Inspection for foreign body contamination

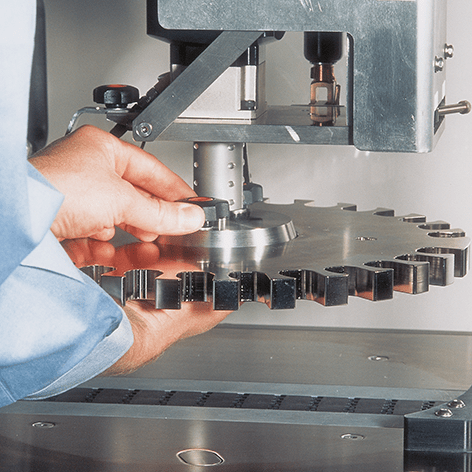

Krechlok says that when it comes to the mixing area for powdered products, Mettler-Toledo offers the gravity fall option to detect the foreign contamination within the powders. In capsules, there is the critical control point of contamination when it comes to the capsule machine, and for this, the Tableaux product is aimed at capsule inspection.

“After the blister machine, for example, we can use an X-ray machine. When the blisters pass the blister packaging station, we offer the solutions for security check where we have different products for aggregation and realization,” she goes on. Pries adds that the individual tablets get inspected for foreign body contamination, including metal contamination in their inspection solutions.

Checking for packaging defects

Mettler-Toledo’s survey inspection devices are the primary reason behind its strong presence in the pharmaceutical market. The survey inspection devices offer visual inspection by cameras and also allow OEM integration. MT’s solutions also verify visual inspections, for example, detecting a missing tablet in a blister or a broken tablet in a blister. Thus, a wide range of inspections can be covered by vision or camera inspection.

Indian pharma companies & co-packing facilities

India is a strategic market not only directly related to the pharmaceutical companies but also for a large number of co-packers or contract packers. Mettler-Toledo in India has a significant market share in the country’s pharma packaging operations segment. “The high flexibility of Mettler-Toledo products and the easy line integration could be a huge argument from our side for the co-packer industry in the country,” points out Krechlok.

Pries adds, “Indian co-packers and local pharmaceutical companies are also working globally and export their drugs to Europe and North America and other territories. They need to know that we are not only experts in product inspection but also experts in international regulations and compliance. All our products comply will comply with the USFDA or European authority standards or standards in India and other Asian countries.”

Compatibility with inkjet marking systems

Pries explains, “We carry our vision contamination and check-weighing products. In many cases where we do not carry our own products, we partner with the preferred supplier of our customers and integrate third-party equipment into our products if it is required. Domino, Videojet, and Markem-Imaje are some of the coding and marking companies that we work with.

“If you touch the pharmaceutical industry, Domino is the global market leader. We have also done laser branding with Aczet laser. We work with these third-party partners and make sure that the different devices will communicate with each other so the printer would require data from us and we make sure that the protocols are in line and the printer will understand our message. This is, by the way, also valuable when you talk about integration with the PLC (programmable logic controller). We have a close relationship with Siemens or with Allen Bradley and consultative services are a very strong part of our business.”

Mettler-Toledo addresses liquid pharma trends

The Covid-19 pandemic and the ensuing vaccination drives saw a high-end demand for pharmaceutical medicines in the liquid area in India and all over the world. This emerging trend inspired Mettler-Toledo to develop new products for the liquid pharma segment, namely, the StarWeigh checkweigher for high precision weighing of liquid pharmaceuticals and the Mettler-Toledo T60 Integrated 360 Series, providing advanced track and trace capabilities to the pharma market for round objects such as bottles and vials used in liquid medicine packaging.

The rising demand for liquid formulations also gave the company a higher demand for its product inspection solutions in the country. According to Krechlok, “We see that the trend with liquid pharmaceuticals is growing and we will develop new products, according to the new trends.”

NOTE — This article is from the February issue of Packaging South Asia which will be posted to readers on 4 February 2022.