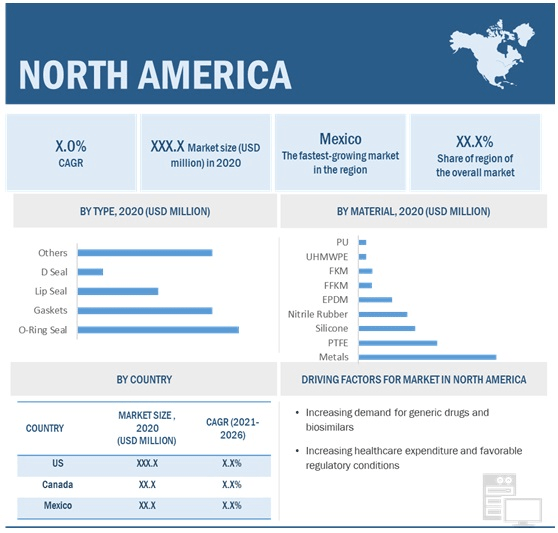

The report “Pharmaceutical Processing Seals Market by material (Metals, PTFE, Nitrile Rubber, Silicone, EPDM, FKM, FFKM, UHMWPE, PU), Type (O-Ring Seals, Gaskets, Lip Seals, D Seals), Application (Manufacturing Equipment), and Region – Global Forecast to 2026″, The pharmaceutical processing seals market is projected to grow from USD 2.1 billion in 2021 to USD 3.3 billion by 2026, at a CAGR of 10.0% during the forecast period. The growth of the pharmaceutical processing seals market is attributed to the increased demand for pharmaceutical manufacturing equipment due to the growing healthcare industry and increasing consumption of pharmaceutical drugs. In addition, the expansion of the healthcare industry in APAC due to favorable trade policies proposed by the government of countries in this region is expected to drive the pharmaceutical processing seals market.

O-rings are the largest type of pharmaceutical processing seals

O-rings are the most preferred type of seals used in the pharmaceutical industry due to their cost-effectiveness and wide range of applications. O-rings are used in static or dynamic applications in pharmaceutical equipment. Applications such as pump shaft and cylinder pistons used in the pharmaceutical industry mostly consume O-rings. O-rings are made of materials such as EPDM, silicon rubber, fluorosilicone, and others, which are highly compatible with pharmaceutical equipment. O-rings are used in agitators and hydraulic cylinders. The increase in the demand for such types of equipment due to increasing pharmaceutical production is expected to drive the pharmaceutical processing seals market.

Silicone is the fastest-growing material for pharmaceutical processing seals

Silicone is the fastest-growing material for pharmaceutical processing seals. There are very few substitutes available in the market for silicone used in pharmaceutical processing seals as it is considered the most suitable material due to its non-reactiveness when it comes into contact with process fluids. In the pharmaceutical industry, silicone is used for making O-rings, gaskets, and diaphragms which are further used in mixers, pumps, valves, piping flanged joints, transfer equipment, hygienic pipework, reactor vessels, and blenders. The increase in the demand for different types of pharmaceutical manufacturing equipment is expected to drive the market for silicone-based pharmaceutical processing seals.

APAC is the fastest-growing market for pharmaceutical processing seals

APAC is projected to be the fastest-growing pharmaceutical processing seals market. The growth of the APAC pharmaceutical processing seals market can be attributed to the growing investment in capacity expansion of the healthcare industry, along with the increasing pharmaceutical equipment production due to the favorable rules and regulations in the region. Additionally, the growth in the demand for new and improved pharmaceutical drugs catering to critical medical conditions has boosted the need for domestic pharmaceutical manufacturing, which is expected to drive the market for pharmaceutical manufacturing equipment and thus, increase the demand for pharmaceutical processing seals in the region.

Most active players in the pharmaceutical processing seals market

Trelleborg AB (Sweden), Freudenberg Group (Germany), Flowserve Corporation (US), James Walker (UK), Parker Hannifin Corporation (US), Saint-Gobain S.A. (France), Garlock (US), John Crane (US), IDEX Corporation (US), and Morgan Advanced Materials PLC (UK) are the leading players operating in the pharmaceutical processing seals market.