Regarding pharma and health products, tracking and safety are essential features of well-designed packaging. As a countermeasure for drug counterfeiting, packaging designers and suppliers are optimizing designs and serializing products to prevent the spread of unsafe and fake medications.

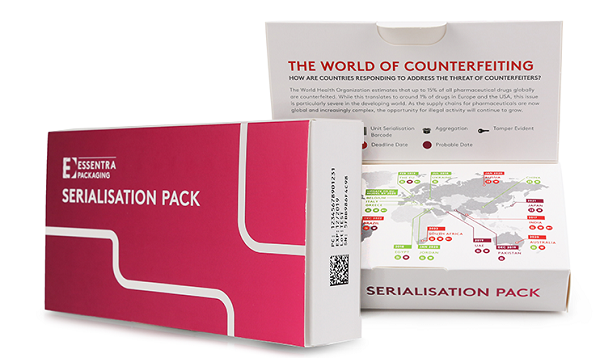

Essentra Packaging offers comprehensive secondary packaging solutions for pharmaceuticals, health, and cosmetics markets. This includes solutions to counter counterfeiting drugs and coding. As identified by the World Health Organization, up to 1 of 10 sold medicines are fake or counterfeit, making it a tough challenge that needs effective solutions. The lack of rigorous testing and safety protocols makes such drugs a public safety hazard.

As a response, packaging designers and manufacturers like Essentra Packaging are developing new packaging designs for branded, authentic drugs, including serialization.

Packaging serialization helps in identifying and tracing product

Packaging serialization refers to the process of allotting a code to the packaging of a pharma product or drug so that it is uniquely identifiable and traceable to the product. This works as a measurable, traceable, and anti-counterfeit method of identifying each product.

Earlier, only batch numbers and expiry dates were printed mandatorily on the packaging of medicines. While it was relevant, it wasn’t enough. With the rise in counterfeit and inauthentic medicines and the apparent threat to public health, serialization became a necessary protective element.

While it is necessary, it is difficult for small businesses not equipped to handle the challenges associated with supply chain difficulties relating to coding and data management. Now, serializing has become mandatory with specified data and structure of details that vary in form between countries but remain similar. Serial coding is done during both- the primary and secondary packaging process. It is automated to connect data directly and minimize human involvement.

Benefits of serializing pharma products

The primary benefit of serialization is the unique identification of every unit of pharmaceutical products manufactured such that they can be traced and authenticated independently.

It helps track details related to origin, batch reference, expiries, conditions, and more for each unit to facilitate tracing, storing, monitoring, and optimizing.

An experienced and dedicated partner ensures quality and is essential in pharmaceutical packaging. Essentra Packaging handles concept creation to delivery and makes serialization straightforward.

Their cost-effective, agile, and precise solutions make them ideal pharma partners to complement and simplify existing processes in serializing pharma packaging. They support standard code formats as well as custom solutions.

Committed to delivering excellent quality irrespective of complexity or length of the print run, they verify human and machine readability codes and validate them using multiple software.

Clear Code can differentiate the products with high-quality codes

Essentra Packaging offers Clear Code, which provides versatility and performance. It is a coding system that creates high contrast images on a hardy coating using a proprietary color-changing technology having low/high wattage CO2, fiber, or UV laser.

The technology is a simple add-on to the packaging production process. It is beneficial over conventional ink coding, etching, and thermal transfers by providing superior scuff resistance, faster line speed, and producing high-quality codes and contrast.