Lumus, the pioneering innovator of reflective waveguide displays for Augmented Reality (AR) devices, has joined forces with Schott, the leading supplier to the growing AR industry. Based on a strategic partnership agreement between the companies, Schott has built a manufacturing setup to supply Lumus’ core technology, the Lightguide Optical Element (LOE), based on reflective waveguide technology.

International technology group Schott, the worldwide leader in the manufacturing of optical materials and components for Augmented Reality (AR) waveguides, announced that it has joined forces with Israeli company Lumus, the pioneering innovator of reflective waveguide displays. Under the agreement, LOEs offered by Lumus, including the brand-new and pioneering Lumus Maximus, are now manufactured by Schott.

“Lumus is truly proud to announce this strategic partnership with Schott to enable mass-scale manufacturability of our waveguides at a competitive cost,” said Ari Grobman, chief executive officer of Lumus. “With our upcoming ‘Maximus’ 2D waveguide architecture ready to take advantage of the fast-approaching consumer AR market Schott is the ideal partner to help scale our unique technology.”

The partnership adds a new product line to Schott’s offerings to the AR industry. Schott’s groundbreaking RealView high refractive index glass wafers are already a key enabler for AR devices using refractive waveguide technology with ever-wider field-of-view (FOV). Under the new partnership, Schott broadens its technology offer to the market, in manufacturing optical components based on reflective waveguide technology.

“Reflective waveguides are acknowledged for excellent image quality. Achieving this quality requires the tightest control of manufacturing processes. Schott’s integrated set-up covers all relevant process steps from material science, melting, processing of substrate and coatings, to final assembly and metrology. That level of control allows us to meet extremely tight manufacturing tolerances at favorable costs,” said Ruediger Sprengard, head of Augmented Reality at Schott. “Reflective waveguide LOEs complement our product portfolio, giving our customers the option to pick the technology suited best for their application and underline our commitment to the AR industry.”

An emerging industry – looking for optical excellence

AR or MR devices are on their way to end consumers. The innovation roadmaps of leading tech giants around the globe include AR solutions as the “next big thing” in consumer electronics. End user-adoption of this technology requires uncompromised image quality, widest FOV, and a small, sleek device light enough to be worn on the face comfortably for extended periods. The AR or MR industry has devoted significant resources to achieve these goals, while meeting the retail price demands of consumers.

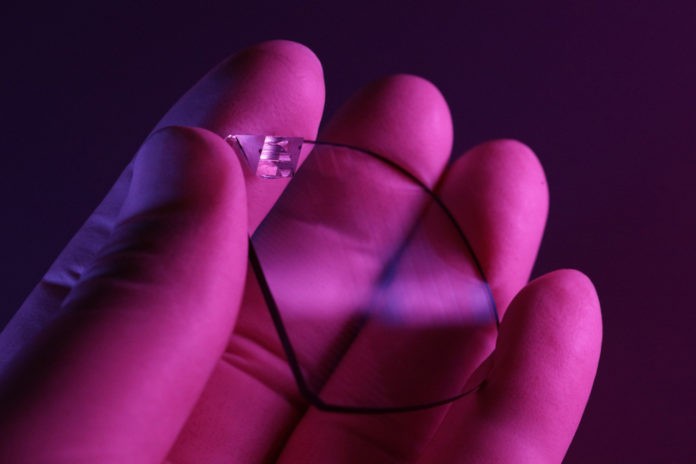

The AR or MR industry widely believes that a waveguide-based optical design will be a key enabler for end consumer adoption. Those waveguides require an optical glass of most pristine quality and surfaces manufactured to unprecedented precision to deliver images with uncompromised quality. Schott is serving AR or MR innovators worldwide as the leading provider of waveguide materials. Within this segment, Schott’s customers use different technologies to manage the input and output functionality in such waveguides, among which surface gratings and volume holographic structures, all of them already using Schott RealView wafers defining the industry reference in quality and mass manufacturing maturity. Another waveguide technology, widely acknowledged in the market for its image quality, is the reflective waveguide approach pioneered by Lumus.

When making their choice, product designers have to make their technology selection between different trade-offs in image quality, power efficiency, FOV and manufacturing readiness.

Lumus and Schott team up to reshape the future

Within this cooperation, Lumus is responsible for research and development on the optical design of the reflective waveguides, as well as their commercialization. Schott’s focus is the manufacturing of the LOEs, leveraging its international production network with high-end optical glass melting in Germany; its field-proven substrate processing lines in China, operated as a joint venture with Crystal-Optech, being already the hub for Schott RealView, and its component factory in Malaysia, where the LOE assembly line is located. Dedicated engineering hubs in Germany, Switzerland, and China support required process innovation and metrology development.

An optical glassmaking heritage

Schott, the inventor of specialty glass, is fully committed to enabling the future of Augmented and Mixed Reality with outstanding optical glass components. The company’s scientists and #glasslovers worldwide keep on fueling the AR innovation pipeline, based on a proven and scalable mass-production-ready ecosystem.