From its inception two decades ago as a manufacturer of converting machines, Jupiter Laminators has since acquired an formidable reputation across India as a manufacturer of flexible packaging materials for several market segments including food, beverage, healthcare, pet care, and industrial goods. It has also established itself as a supplier of packaging materials that contain security and anti-counterfeiting features to protect brand value.

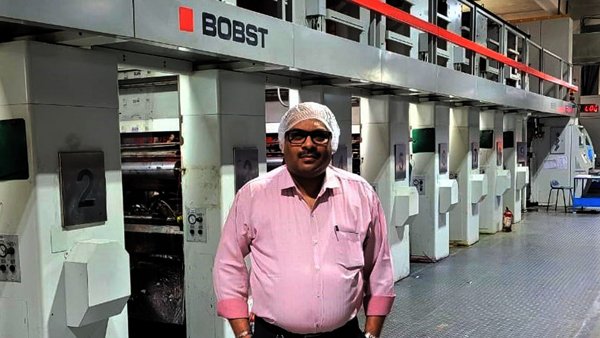

The company first invested in a Bobst 5002 rotogravure press, in 2017. Impressed by its performance and results, Kaushik Nag, CEO-Flexibles & CPP at Jupiter, speaks about the recent order of two further Bobst machines – the Nova RS 5003 and the Vision CI flexo press. The assets will be installed at Jupiter Laminator’s new 65-acre integrated plant in Murthal, 10 kilometers from the company’s Sonipat plant, just north of New Delhi. Kaushik looks back on the reasons for the company’s earlier investment in a Bobst gravure press and how the successful experience of this machine led his organization to choose the two new presses for the new integrated Murthal plant from the same company.

For which applications do you use your existing Bobst 5002 gravure press?

Kaushik Nag – It is used for printing on film, paper, and laminates for flexible packaging.

Which features of the printing press persuaded you to buy it?

KN – We carried out a lot of research before buying and compared numerous presses against each other to ensure that the one we chose would do exactly what we required. We knew we were looking for a press that would be cost-effective while delivering sustainable production. Bobst was able to demonstrate that their machine could do just that. We also liked the registration system, the shaftless mechanism of the cylinder, and the fast job setting. The unique twin flow dryer for more efficient drying also proved a selling point for us.

What have been the production benefits?

KN – We have been able to achieve consistently high print quality, on a wide range of materials including eco-friendly substrates. In addition, we have noticed a significant reduction in wastage since its installation. Features such as effective web handling, accurate tension control from unwinder to rewinder, fast job changeovers, wastage reduction, and print quality consistency have all helped to boost and improve our production. For us as a business, consistency is critical as it enables us to offer a uniform quality to our clients.

How user-friendly is the machine?

KN – The machine is very operator-friendly, and our operators are very happy operating it. Today, we run most of our jobs on it, including the important job runs, purely because of the consistently high-quality print that it delivers time and again.

Has the press provided a strong return on investment for Jupiter Laminators?

KN – Absolutely! For any converter looking for maximum uptime, ease of operation, high-quality print, and advanced sustainable solutions, Bobst can deliver. We have not had any issues with the machine and the service has always been timely. I give the press five stars for quality, reliability, and value for money!

(This is an edited version of a Bobst press release, edited by Packaging South Asia)